After some twists and turns, the life of most plastics reaches an end once they land in a trashcan. From there, some are sent to landfills and incinerators, others pile up in the open, and still more flood the ocean, where they are slowly decomposed into microplastics.

But what if these plastics could be given a second life? That’s the mission at the heart of P.E.T. (Plastic Ecological Transformation), a Chinese company that recycles plastic bottles into beautiful, customizable textiles.

China — the world’s leading polluter in plastic waste — has long suffered from deficiencies in waste regulation. Before July of this year, when Shanghai became the first city in China to enforce mandatory waste sorting, the nation had no such laws aimed at large-scale waste separation by the public, and plastics continue to be a major source of pollution in the country.

Related:

Shanghai Has Radical New Recycling Laws and People are Going CrazyShanghai’s residents are trash talking, with new recycling laws fueling garbage-sorting apps, clothing, and virtual reality experiencesArticle Jul 02, 2019

Shanghai Has Radical New Recycling Laws and People are Going CrazyShanghai’s residents are trash talking, with new recycling laws fueling garbage-sorting apps, clothing, and virtual reality experiencesArticle Jul 02, 2019

Perturbed by the polluted country that her children will one day inherit, mother of two Jane Zhao decided to tackle the problem of raw material waste herself. She founded P.E.T. using her years of working in fashion manufacturing, and in doing so tapped into a substantial gap in waste management systems, not just in China but worldwide.

According to data on the recyclability of different types of plastics, around 52% of the plastics we manufacture are recyclable. But of the astronomical amount of plastic waste humans generate, only 9% actually ends up being recycled. P.E.T. looks to change that. Specifically, they mine bottles for a material known as rPET (short for “recycled Polyethylene Terephthalate”), from which P.E.T. also gets its name.

The fashion industry is notorious for its environmental impact, consuming over 70 million barrels of oil and 1.5 trillion liters of water each year. But Zhao says that rPET has the potential to make a positive impact in this regard. If prepared in mass quantities, it can be used to substitute a popular fiber that makes up over 60% of our clothing: polyester. Not only is polyester manmade, but most of the industry is also dependent on first-hand, petroleum-based polyester, with an annual production weighing over 76 million tons. “By doing this,” says Zhao, “not only could we reduce our dependence on petroleum and raw materials, but also attain similar product quality.”

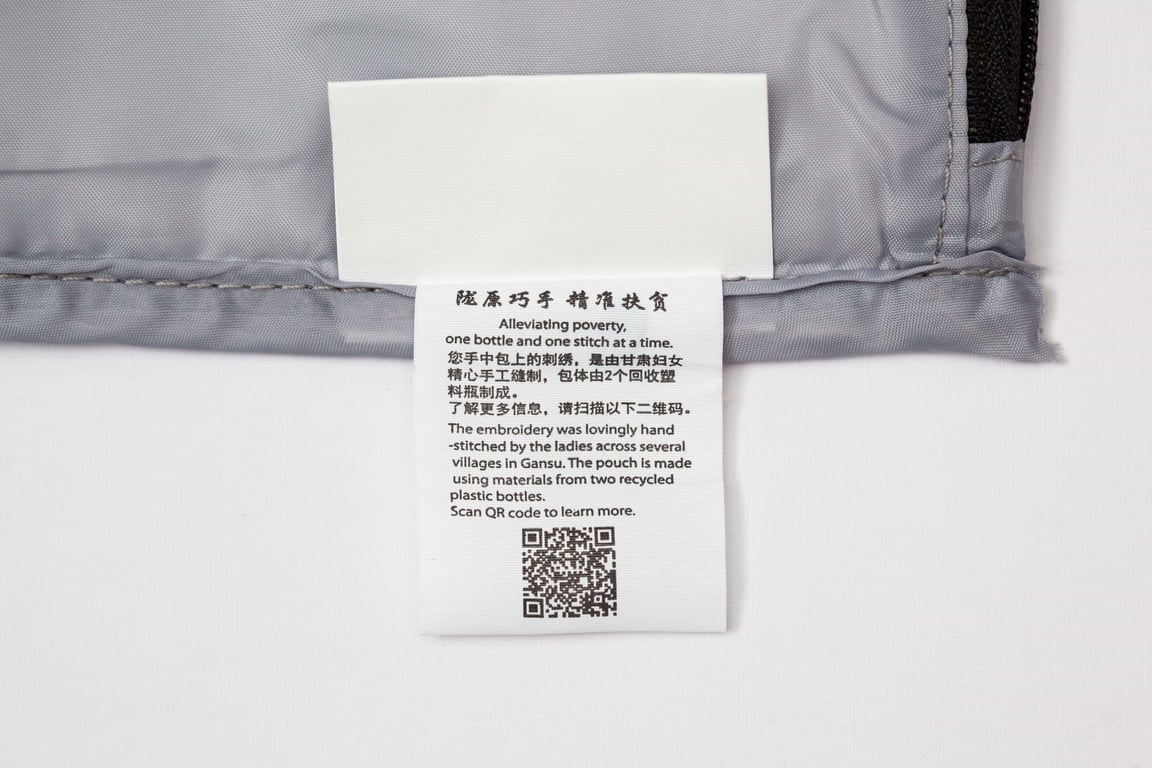

P.E.T. processes this “recycled polyester” in-house, and sells it to multi-national corporations like Microsoft and Coca-Cola — which usually have global sustainability commitments — as well as an increasing number of domestic companies like JD.com and retailer Urban Revivo. They’ve also produced products of their own to target individual consumers. These silk-textured scarves, “canvas” bags, tablecloths, and sneakers — sold on their WeChat official account — are similarly made with certified and traceable recycled plastic bottles.

In the past year, P.E.T. successfully recycled 110,000 bottles from traditional waste streams. But Zhao isn’t expecting to revamp the industry with her small business — rather, she wants to set an example for bigger fish. “Our ultimate goal is to cultivate waste-conscious thinking in both individuals and corporations,” explains Zhao, “so they can reach for more sustainable products, thus driving more changes in the industry.”

When Zhao first established P.E.T. in 2017, she says the awareness of green-labeled products in China was fairly low. But today, she’s noticed a significant shift in the way customers view the environmental cost behind their consumption. “The change in people’s attitude is a direct result of the government’s increasing effort in waste management,” Zhao explains, pointing to the increasing education and publicity campaigns in schools and neighborhoods around recycling.

Nevertheless, green-labeled products still comprise only a small percentage of the current Chinese market. One hurdle is the higher-than-average price tag on green products. To fix that, Zhao thinks that companies should also be focusing on balancing the supply chain to maintain a reasonable price point. “Buyers should not feel compelled to pay more just for green labels,” says Zhao. “In the end, it’s the quality and the design that attract them, combined with the intent to reduce environmental impact.”

Related:

“Nobody Likes Waves of Trash”: China’s First Pro Surfer Turns Eco WarriorHainan-based Chinese surf star Darci Liu on her hopes to follow in Yao Ming’s environmentalist footsteps and to produce China’s “Blue Planet”Article Oct 25, 2018

“Nobody Likes Waves of Trash”: China’s First Pro Surfer Turns Eco WarriorHainan-based Chinese surf star Darci Liu on her hopes to follow in Yao Ming’s environmentalist footsteps and to produce China’s “Blue Planet”Article Oct 25, 2018

Another barrier lies in the market’s inconsistency of supply. Though rPET became a certified material decades ago, the quantity and quality of PET plastic still fail to meet the large demand of the textile industry due to a lack of regulation of the raw material — that is to say, the waste itself.

But laws such as Shanghai’s new recycling mandate may prove to be a game-changer. As garbage sorting is strictly enforced, Zhao predicts an increase in the supply of clean, high-quality rPET, which in turn enhances the grade and volume of recycled crafts companies like hers can produce.

Zhao (front right) with members of her team

It takes time for new habits to replace old ones, and fixing our planet’s grave problems requires contributions from all levels — law enforcement, corporations, and individuals alike. But if Chinese consumers start questioning the life cycle of the products they use — and companies like P.E.T. help inject innovative solutions into this cycle — a sustainable solution to our colossal waste problems may just be within reach.