Last year, Chinese State media agency Xinhua caused China Twittersphere uproar by claiming that the country is home to the invention of mobile payments, e-commerce, dockless bike-sharing and high-speed rail — “4 modern inventions” that are supposed to echo the “4 historical inventions” of gunpowder, paper, printing and the compass.

The claim is a stretch. These “inventions” are more micro-innovations, taking leads from other countries, which China then scaled extraordinarily quickly. Yet regardless of the truth behind this bold claim of inventing things that were, well, already invented, real progress is occurring on the ground in China when it comes to innovation.

Smart Factory Kunshan (SFK), a company created by the local government in Jiangsu Province and German-led firm Startup Factory, is hoping to foster and capitalize upon these efforts to innovate. The aim of the joint venture — housed in the city of Kunshan, an urban sprawl sandwiched between Shanghai and Suzhou — is to “co-innovate” manufacturing processes and facilitate a sharing of resources.

It’s kind of like if WeWork, the world’s most valuable shared office space, and Siemens, the world’s largest manufacturer, had a baby.

That’s not exactly how they market it of course. Here are a few lines from the official SFK blurb on the project:

The purpose of the factory […] is to create an innovative environment for empirical research and advanced training. We enable international and Chinese companies to integrate and demonstrate their technology in the field of Industry 4.0 in a realistic production environment.

“Industry 4.0” is Germany’s nationwide push to improve the intelligence and quality of manufacturing output. Sound familiar? That’s because it’s the German version of China’s “Made in China 2025” strategy, something which has had the Trump Administration so rattled recently that Chinese officials have reportedly ordered media outlets to tone down some of the related rhetoric.

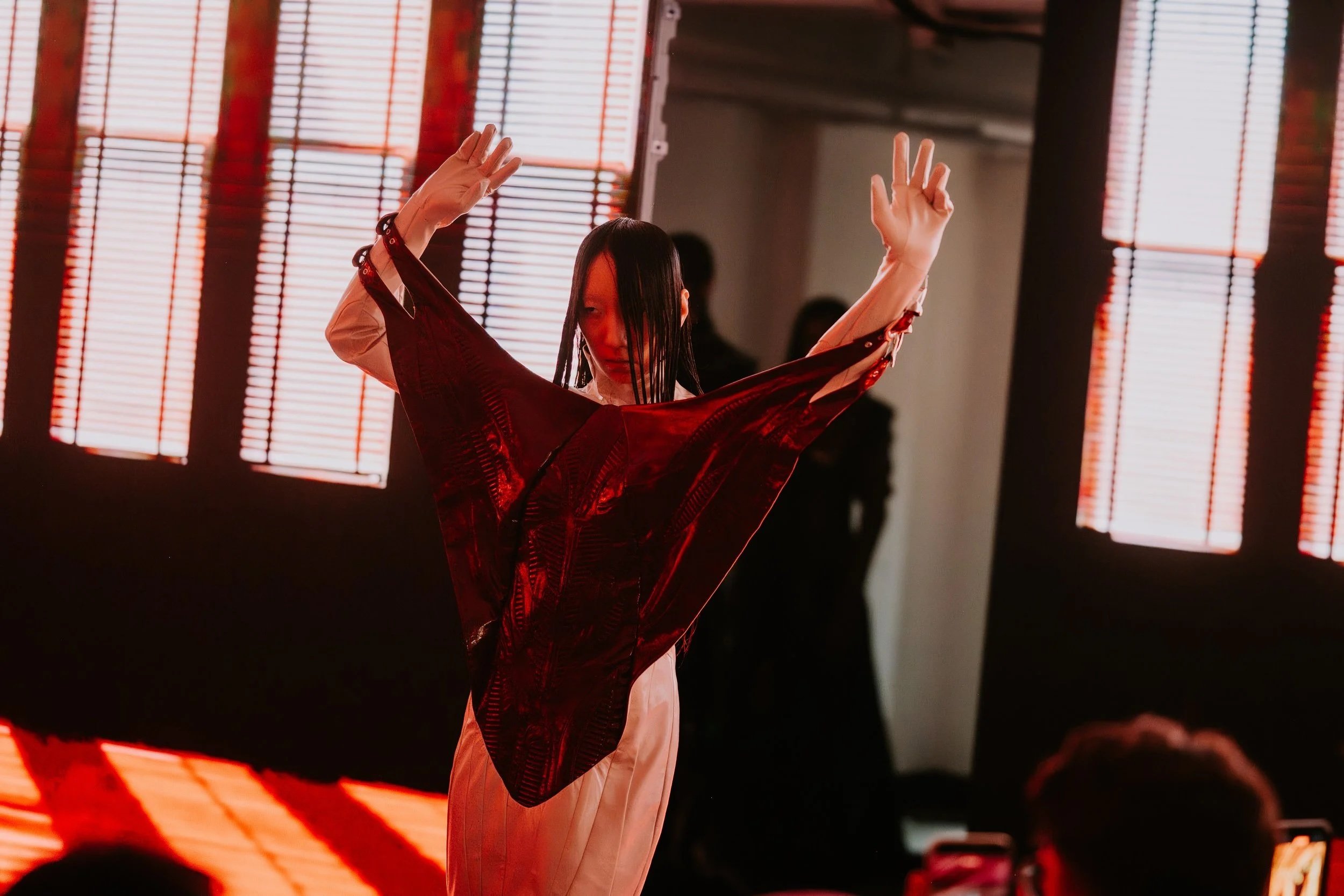

2017 Kunshan Digitalization Summit at SFK

Walking into SFK is both shocking and impressive. You can’t get away from the industrial-meets-hipster vibe as you walk in past the production lines and ping pong tables (admittedly in different spaces), where people from completely different companies work and play together.

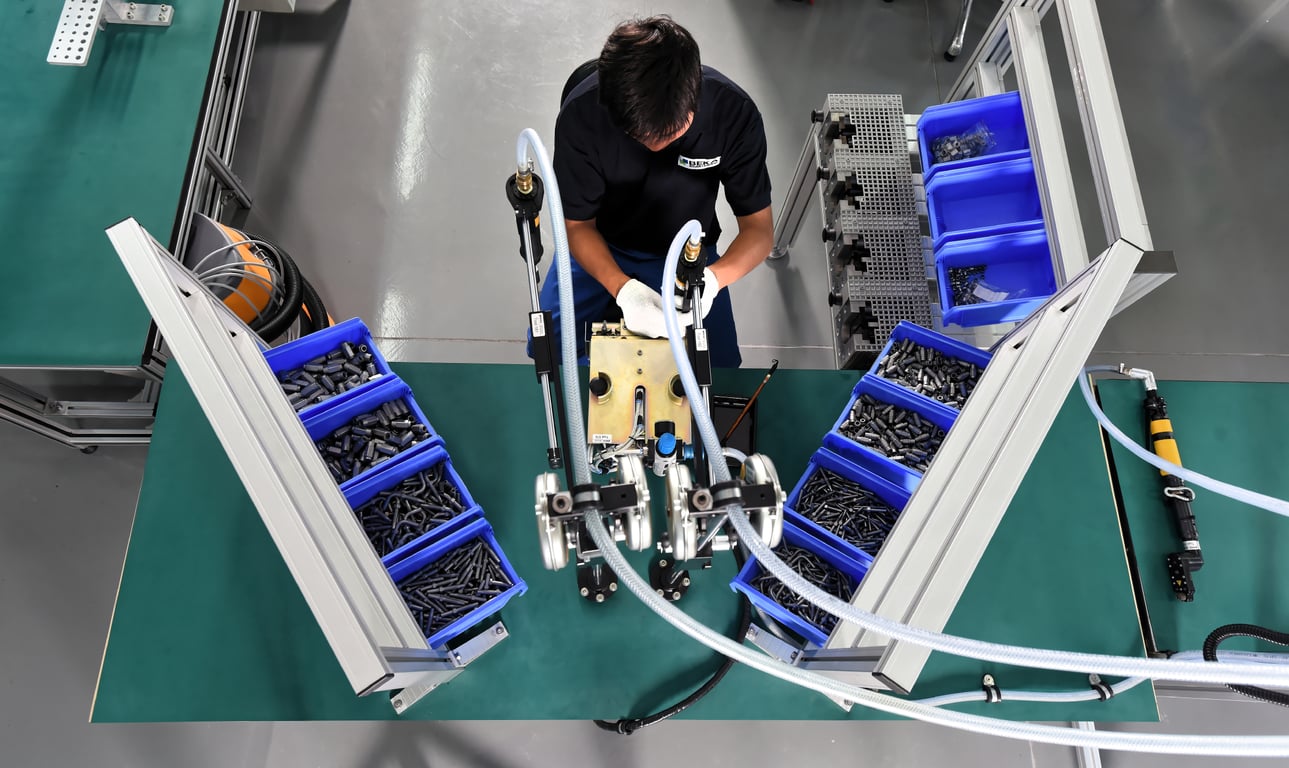

Members can rent everything from office space to forklift trucks, and a whole range of small and medium businesses are at work here, from manufacturers of auto parts to producers of lubricant systems and multi-use plastic.

Unimatic Automation Kunshan at SFK

So far, only Phase I and II are open; Phase III, where most innovation will happen, is currently under construction. When it it becomes fully operational next year, SFK will be able to utilize R&D software tools that simulate automation to help its manufacturers create and test new products and make improvements to their assembly lines, for example. This will empower companies not only to manufacture in China but innovate there too, all by leveraging “shared economy” principles.

Such a “sharing” of knowledge and resources is not without its challenges however. Christian Dorfmueller, SFK Managing Partner, says he often has to dispel fears of forced technology transfer when talking to European companies wanting to manufacture in China. Dorfmueller notes that this is largely misguided because companies, “don’t give know-how by manufacturing. If the product is successful, you will be copied wherever you are based.”

Dr. Schenk Inspection Systems Kunshan at SFK

Dortmueller goes on to emphasise that, “China will grow regardless, whether we engage or not. So, it is better to compete now in China than from afar later.”

Mr Trump, if you’re reading, take note. China may have built its wall hundreds of years ago, but its manufacturing industry looks set to leave the old days behind. SFK, by supporting Sino-international cooperation in smart manufacturing, is one of the players helping them to do so.

—

Cover photo: BEKA Lubrication Systems Kunshan, at SFK; all images courtesy SFK.

You might also like:

Coming Up Next: 3D-Printed, Driverless CarsArticle Mar 22, 2018

Coming Up Next: 3D-Printed, Driverless CarsArticle Mar 22, 2018

Who are the Chinese Brands You Keep Seeing at the World Cup 2018?Article Jun 20, 2018

Who are the Chinese Brands You Keep Seeing at the World Cup 2018?Article Jun 20, 2018

Made in China 2.0: How Li-Ning Sneakers Went from Beijing Outlets to New York Fashion WeekArticle May 22, 2018

Made in China 2.0: How Li-Ning Sneakers Went from Beijing Outlets to New York Fashion WeekArticle May 22, 2018