If you’re a frequent RADII reader, you might recognize the name: Dr. Wayne Song came onto our radar a few weeks back when we heard about the NRG COSIA Carbon XPRIZE, a global competition to convert CO2 emissions into valuable products. Ten teams from five different countries are judged on the amount of CO2 they convert as well as the quality of their products, and with Dr. Song leading the Chinese team, we felt we had to go back in to find out what exactly that entails.

A little background:

A Chinese Team is Aiming to “Turn Carbon into Dollars” in WyomingArticle Apr 12, 2018

A Chinese Team is Aiming to “Turn Carbon into Dollars” in WyomingArticle Apr 12, 2018

Outside of the competition, Dr. Song is a highly accomplished technologist, having worked in a broad range of fields. He’s worked and studied with some greats across different departments, universities, and continents, and has introduced key technologies to China before anyone else. Perhaps more compelling, Dr. Song feels he’s cracked the code to some degree — his carbon conversion technology could be the missing solution to China’s rising CO2 output, and the smog trapped in major cities by greenhouse gases.

We sat down to learn more about the competition, Song’s own 30+ year journey in science and technology, and why he feels China has no choice but to take a serious stand against climate change.

To start off, maybe you could tell us a bit about yourself, and about Carbon X Prize?

Thinking back, I’ve been through many universities, in China, Canada, and the US. Peking University for my bachelor’s degree, and Qinghua University for my master’s, both of which were in Beijing. After which I came to Canada, got my PhD at McMaster, and my Post Doctor Research Fellow at University of Toronto. After working for a while I became an adjunct professor at University of West Virginia and University of Maine. When I was back in China, I was invited to be an adjunct professor at Beijing University of Chemical Technology, then Nanjing University of Forestry.

As for majors, I’ve been through seven engineering disciplines: mechanics, civil engineering, chemical engineering, mechanical engineering, computer engineering, material science, and wood engineering. All those experiences really gave me a multi-disciplined background, and at first it was difficult to find a job. Everybody tells you you don’t belong to their industry. I found out that each industry has its own very specific ways to solve problems. On the other hand, many problems do need a multidisciplinary approach. CO2 elimination and conversion is one of them.

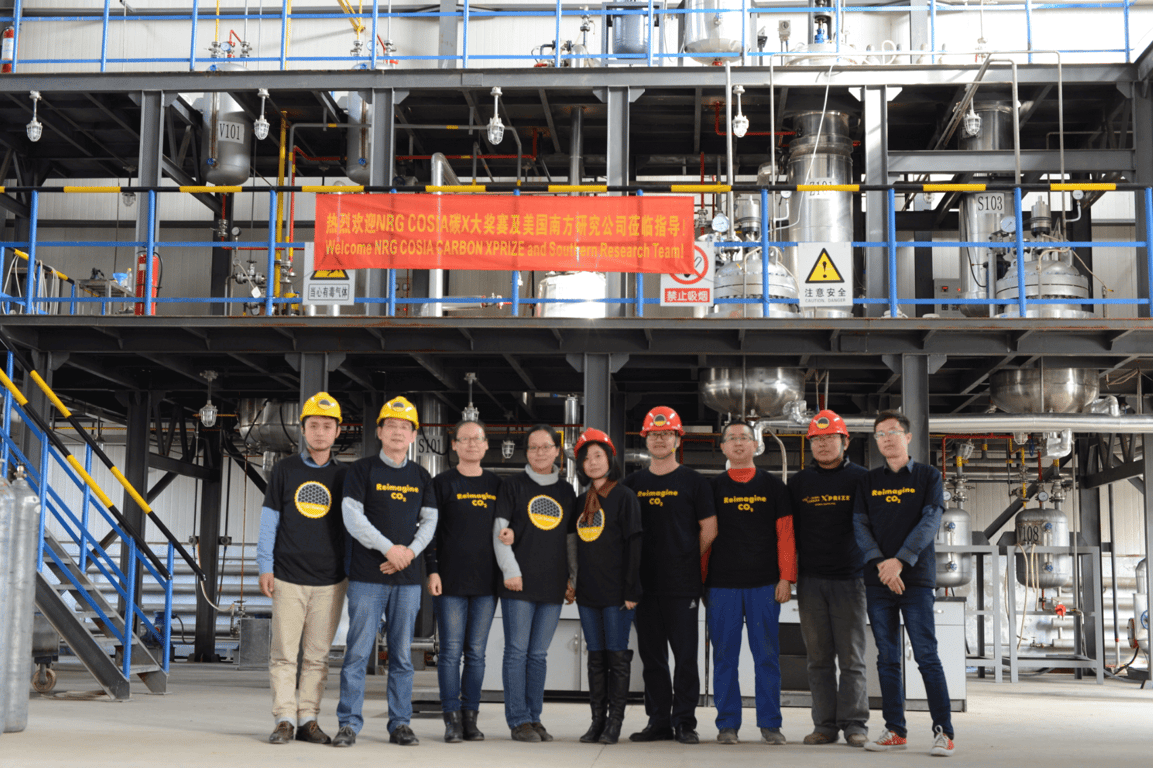

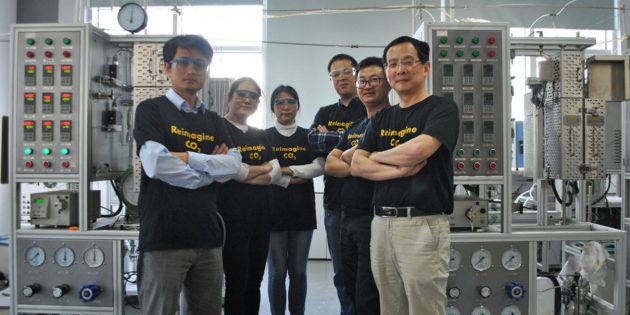

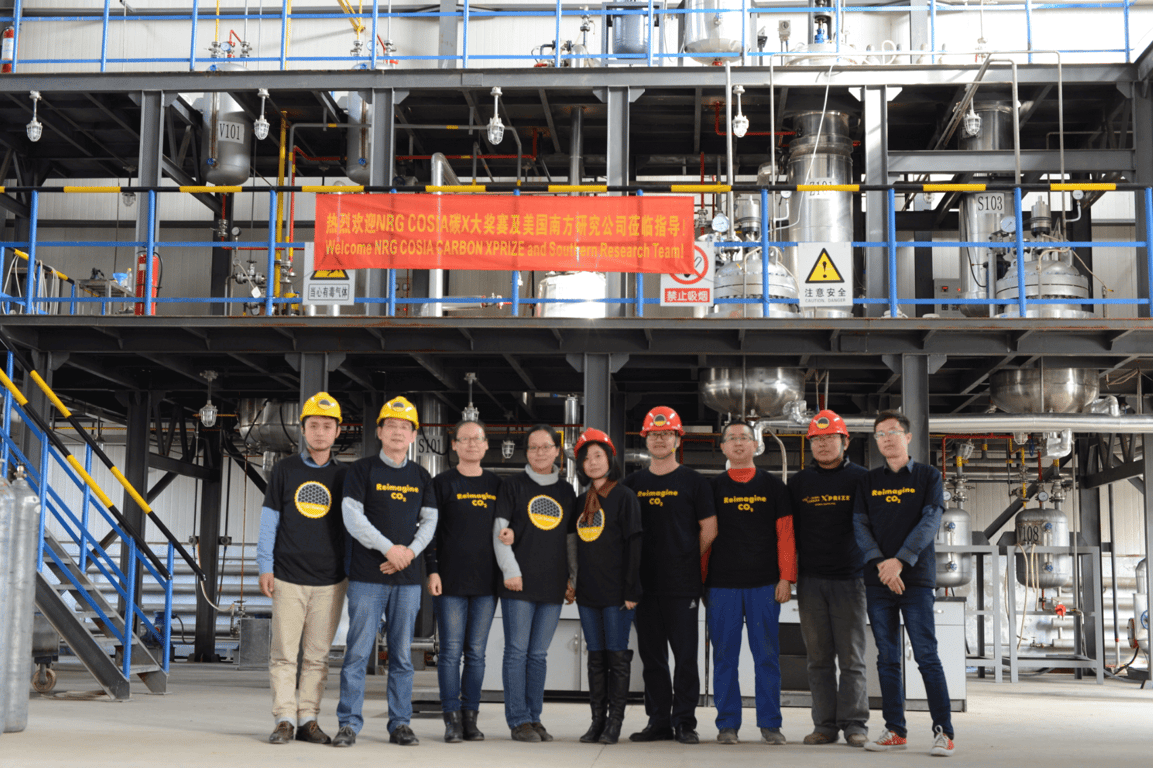

Dr. Song and members of the C4X team (photo: Zhefan Shen)

Three years ago, I was approached by a very famous University of Toronto professor, Geoff Ozin. He’s regarded as the father of nanochemistry. He’s incredibly passionate about what he’s doing, and one thing he mentioned a lot was the Carbon X Prize. It’s not always easy to get information about things like this in China, so I started to help promote the competition and mention it in my lectures. By then, Ozin had already passed his passion for CO2 conversion to me. He gave me the big picture, and shared with me a lot of global perspective — what CO2 means to society, what it means to human beings.

I realized China emits 11 billion tonnes of CO2 per year, about one third of the world’s total emission. So I really did feel obligated to have a Chinese team in the Carbon X Prize competition. I thought China needs to be there, we must be there. So here we are.

As a self-described outsider in the industry, what interested you about the carbon conversion problem?

I first started punching the economic numbers, and gradually I found I may hold the solution to the problem. Right away I realized that converting CO2 into fuel will not make any money at all. The cost of whatever you invested is about ten times what you can get for it. So fuel is not the solution — you have to make high value-added products.

In 2013, I went to Germany to receive the bankrupt biomass-to-fuel company called Choren Industries. My friends, a group of Chinese investors, had bought it. Their goal was to convert wood chips into fuel, and their major investors included Mercedes-Benz, Volkswagen, and Shell. 800 million euros, and it failed.

The C4X Team

That gave me some deep insight into fuel. I realized to make money on that, you needed an oil price of over one hundred fifty dollars per barrel. And there’s the fundamental philosophy problem: oil, natural gas, and coal are created inside the earth over billions of years. They can be dug out and used right away. Man-made fuel cannot compete with God.

[pull_quote id=”1″]

But chemicals, and plastics, and construction material — you can’t dig those out of the earth directly. You need to convert and manufacture them either way, so that’s the direction I think we should be looking. I’ve been working in plastic since 1989, and I realized you could really make a very high value-added product. In 1998 I brought the first wood plastic composite technology into China, and with others, developed it into a 20 billion RMB industry.

So from writing a formula, to how to process it, to designing the tooling, building machinery, to providing the turnkey and getting others on board…I’ve gone through the whole process to bring a technology to reality. And that makes me feel confident about any engineering project, I know I can do it. Just like Elon Musk — he has some vision for humankind, for the world, he really dreams of doing something, and he does it. Even if I’m not on that level of success yet, I do think he and I have some similar qualities, and I know I can accomplish big projects.

What makes your approach to carbon conversion the solution?

Number one is our conversion technology, which is a nanoparticle-sized catalyst to break down CO2 and convert it into other useful chemicals. Our conversion rate is above 95%, and that’s one of Carbon X Prize’s criteria. If the conversion rate is less than 30%, you’re not qualified to join. If it’s between 30% to 50% you can join, but you’ll score zero. You can score with anything above 50%, but ours is consistently above 95%. What’s more is that our process itself is energy-saving. CO2 is normally very stable, and might need to be brought to temperatures of 800 degrees celsius in order to break it down. The cost of doing that is preventably high. Meanwhile, our process works at temperatures of about 120 to 180 degrees.

Number two, we also utilize CO2 as a raw material, converting it to a supercritical state, at which point it can be used to make everyday items like coffee cups, lightweight automobile interiors, and building products, all of which are high value added.

Our technologies as a whole are highly efficient. We can capture CO2 at about 95%, and purify it to 99.9% (food grade), and even 99.999999%, which is electronic grade, and we can do it all for a relatively cheap cost. Our team has many years of experience in the capture stage, so that’s our specialty.

Number three, maybe most important, is economics. Even a couple years ago, our nanocatalysts relied on precious metals, like cobalt. Of course, cobalt is expensive. These days we can use cheaper nanocatalysts to get the job done. So our technology is highly efficient, energy-saving, and economically feasible.

What does it mean for carbon conversion to be economically feasible, in the context of China?

As I said, I’m not just a scientist, I’m an engineer, and a business person. My work converting biomass into useful products taught me what it means to fully commercialize something like this, and from an economic point of view, it’s definitely possible to reduce CO2, and through carbon capture and conversion, even have a negative rate of CO2 emission.

I did a mathematic model, looking at China’s GDP growth five years at a time. From 2016 to 2020, growth is 6%. For the next five years it’s 5%, and for the next five years it’s 4%. But if you increase GDP like this, energy consumption must increase as well. I ran the numbers, and if we don’t do something, China’s CO2 emissions will reach 18 billion tonnes by 2034. That’s half of the world’s emission. To me, that’s definitely unacceptable. The only way to change it is to convert it.

[pull_quote id=”5″]

Then I modeled several scenarios using our technology. Ideally, we begin CO2 conversion now, and sometime around 2022, China’s CO2 emission will reach a peak and start to reduce. Then by 2030, emissions could be reduced to about the level of 2005. By 2034, China’s emissions could be less than three billion tonnes. That’s lower than China’s carbon output in 1999, and it’s the level every country is supposed to reach by 2030, according to the Paris Agreement. China would achieve that goal four years later, but that’s still a huge achievement. If we weren’t to do CO2 conversion, China would be emitting 18 billion tonnes of CO2 per year by then. So really, CO2 conversion is one of the keys.

Dr. Song and the C4X Team

What’s more is that CO2 and China’s pollution smog are linked. The more CO2, the more pollution is trapped in our cities by greenhouse gases. I thought about this all for over a year, then finally, I proposed a unique way to eliminate CO2 and smog from China. My solution is simple, and it’s one sentence: we will not allow any coal power station, natural gas power station, steel, concrete, or any industry with harmful pollutants and CO2 flue gas, to directly emit anything into the atmosphere.

Instead, we would require everything to go through a system to capture, convert, and utilize the CO2. That is our solution, and it’s a very simple, engineering-based approach. If China follows our suggestion, China could solve the smog problem. I can tell you, the difficulty is in economics.

Right now, with China’s current pollution capture and conversion treatment, it already costs too much. Nobody can afford it, many have shut down, and it’s been a blow to China’s economy. The problem is that people are capturing pollution, and letting CO2 go. The CO2 is the moneymaker, and they let it go. That’s the problem.

Song’s team’s testing site, a coal-fueled power plant in Wyoming

I’ll give you some fundamental technical data for context. One approach so far has been to enhance coal burning efficiency. It used to take 390 grams of coal to produce one kilowatt hour of power. Now, we’re down to 300 grams. It’s very impressive, but on the other hand, this one has a limit. How far can you go?

Instead, let’s talk about coal emission. One metric ton of coal can generate 3,333 kilowatt hours of power, which is worth 1,500RMB, and emits around 100kg of pollution. If you wanted to reduce those emissions to zero, it would cost about 300RMB. That’s twenty percent of the revenue.

Currently, Chinese power stations are barely making money, or maybe even losing money, so it’s impossible for them to put down a significant amount of money into pollution reduction. But now consider that one metric ton of coal will emit 2,640kg of CO2. Right now, that’s being emitted into the atmosphere freely, not being used at all. With our technology, we can capture and purify it. That metric ton of coal could produce 3,600kg of ethylene glycol, 1,800kg of methanol, and useful plastics. With all these revenue generators, the CO2 from one metric ton of coal could yield 32,000RMB. That’s about twenty times more than the 1,500RMB revenue from electricity.

With the value generated from CO2, the cost of smog reduction becomes peanuts. So we can easily give one or two percent to perform smog elimination. So now you can see the logic. That’s what we found out while competing in Carbon X Prize — I don’t think any other Chinese scientists have figured out the secret. Professor Ozin told me that in the UK parliament, there’s a slogan hanging that says “embrace CO2 economics.” I fully agree, and right now CO2 to China is not a liability, but a treasure. People have to realize that and seize the opportunity.

You might also like:

Out of the Frying Pan and Into the EngineArticle Sep 14, 2017

Out of the Frying Pan and Into the EngineArticle Sep 14, 2017

Chinese Towers in the News for Reducing Smog, Posing Security ThreatsArticle Jan 17, 2018

Chinese Towers in the News for Reducing Smog, Posing Security ThreatsArticle Jan 17, 2018